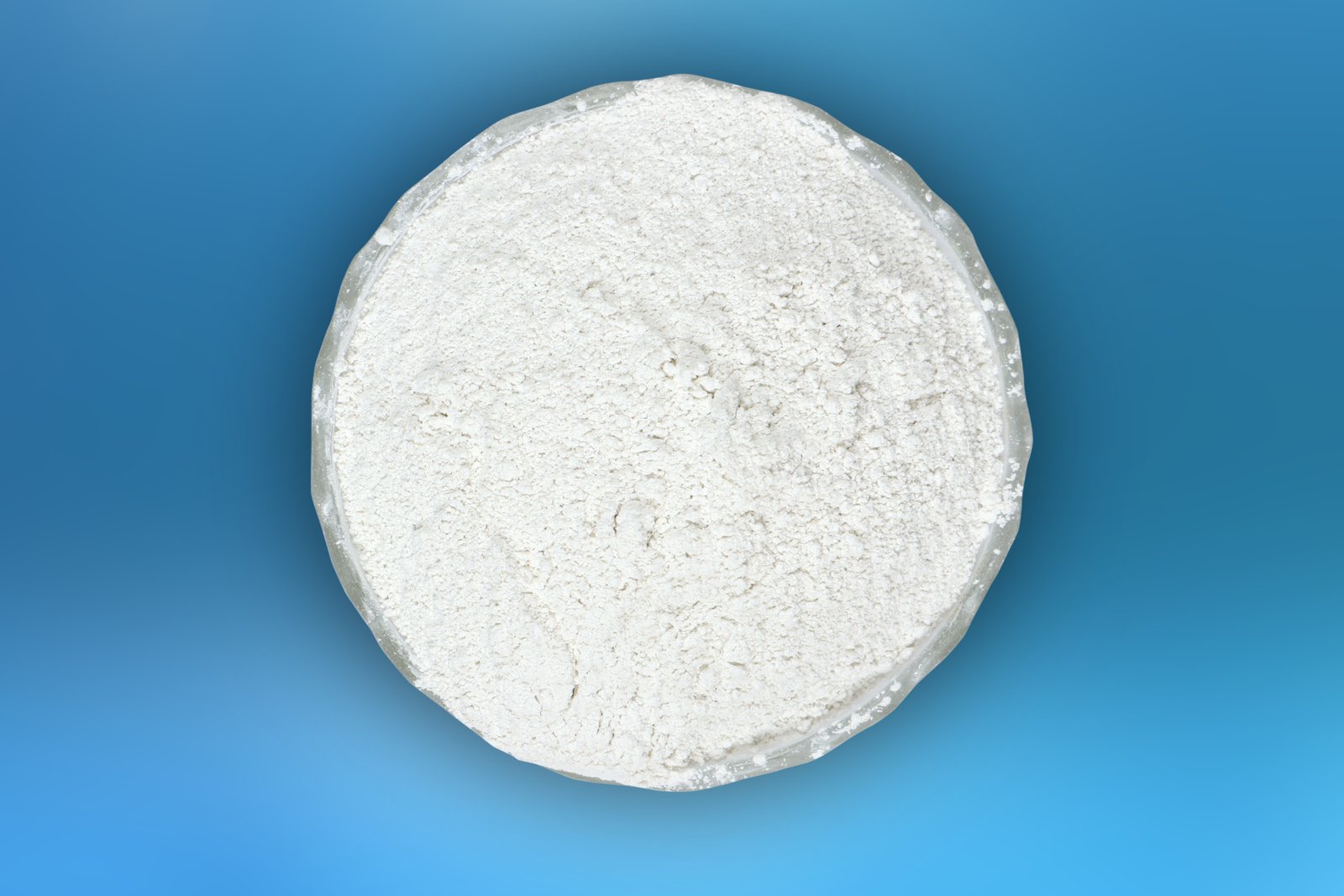

Fine kaolin clay powder for uniform mixing, stable performance, and consistent quality in industrial applications.

White to off-white powder with fine particle size and high whiteness, suitable for ceramics, refractories, tiles, construction, rubber, and foundry uses.

| Material | Kaolin Clay (China Clay) |

| Color | White to off-white |

| Form | Fine powder |

| Style | Hydrous aluminosilicate clay |

| Feature | Fine particle size, high whiteness |

| Application | Ceramics, refractories, tiles, construction, rubber, foundry |

4000 Metric Ton

Supports bulk orders with flexible packing options (25 Kg / 50 Kg / 1 MT) for domestic and export supply.

Share required quantity and destination for availability and dispatch schedule.

HDPE bags / PP bags / Jumbo bags

| Content | SiO₂ | Al₂O₃ | MgO | K₂O | Whiteness | Purity |

|---|---|---|---|---|---|---|

| Typical | 45% – 55% | 35% – 38% | ≤ 0.5% | 1.5% – 3.0% | 75% – 90% | 95% – 99% |

| Specification | Details | Specification | Details |

|---|---|---|---|

| Melting Point | 1750°C – 1785°C | Thermal Conductivity | Low |

| Specific Gravity | 2.55 – 2.65 | Dimensional Stability | Excellent at high temperatures |

| Density | 2.4 – 2.6 g/cm³ | Porosity | Low to medium |

| Strength | Moderate (improves after firing) | Water Absorption | 10% – 18% |

| Hardness | 2 – 2.5 (Mohs scale) | Foam | Nil |

| Moisture | 0.5–1.5% |

| Water Absorption | 40–65% |

| Water of Plasticity | 28–38% |

| Oil Absorption | 30–50 g/100 g |

| Content | Data |

|---|---|

| Hardness (Mohs) | 2.0 – 2.5 |

| Green strength (dry MOR) | 2 – 6 MPa |

| Dimensions stability | Good |

| Handling strength | Moderate |

| Abrasion loss | Low |

| Content | Data |

|---|---|

| Drying contraction | 2 – 5% |

| Firing contraction | 1 – 3% |

| Total shrinkage | 3 – 8% |

| Shape retention | Better than raw clay |

| Thermal Conductivity | 0.2–0.4 W/m·K |

| Firing Temperature | 1100–1300 °C |

| Thermal shock resistance | Good |

| Typical firing soak | 30–90 minutes |

| pH (aqueous slurry) | Fluorine (F) | MgO | Water-soluble salts | Loss on ignition (LOI) |

|---|---|---|---|---|

| 4.5 – 6.5 | <0.01% | 0.05 – 0.5% | <0.1% | 12 – 14% |

| Component | Typical Range |

|---|---|

| Kaolinite | 85–99% |

| Mica / Illite | 0–5% |

| Quartz | 0.5–8% |

| Feldspar / Anatase (trace) | <1% |

Quality checks and documentation to support consistent supply

We follow standard checks to ensure consistent quality and compliance.

Quality, reliability, transparency, and customer support in every shipment.

Any test reports can be shared on request at an additional cost, including third-party testing where required.

Processed grades suitable as fillers for ceramics, paper, paints, and coatings.

Common questions about Kaolin Clay Powder

Kaolin powder is widely used as a mineral filler/extender in paper, paints & coatings, and ceramics depending on the required finish and performance.

Yes, we can discuss your target use-case and align supply parameters where feasible.

Samples and test reports can be arranged on request for evaluation and compliance needs.

Packing can be arranged based on your shipment and handling requirements. Share your preferred packing type and quantity.

Yes, we provide export-ready supply and can support required documentation for shipments.